Have you ever faced glass delamination, poor clarity, or failed safety tests after purchasing what seemed like “high-quality” PVB Interlayer Film?

For glass manufacturers, builders, or automotive suppliers, the wrong choice of interlayer film can mean production delays, rejected batches, and costly replacements. That’s why evaluating PVB Interlayer Film based on clear, measurable quality standards is critical. The following five metrics will help you make confident purchasing decisions and ensure long-term performance.

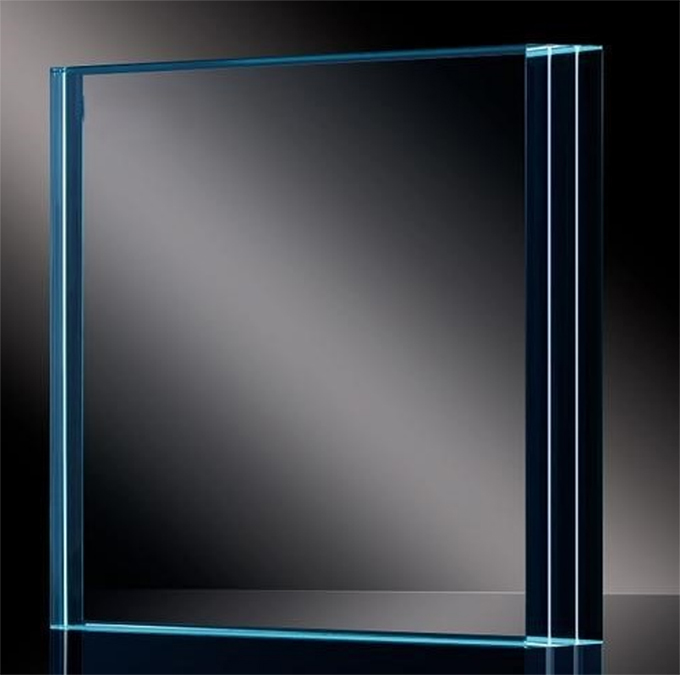

1. Adhesion Strength — The Core of PVB Interlayer Film Performance

One of the most important metrics in any PVB Interlayer Film is adhesion strength. This determines how firmly the film bonds with the glass layers under heat and pressure. Poor adhesion can lead to delamination, bubbles, or cracks over time.

A premium PVB Interlayer Film ensures consistent bonding even under high temperatures or impact. This feature is essential for laminated safety glass used in architecture, vehicles, and public buildings. Always request test data from suppliers showing peel strength and impact resistance results that meet or exceed ISO or ASTM standards.

2. Optical Clarity and Light Transmittance

For industries like architecture and automotive, optical clarity defines product quality. The PVB Interlayer Film should have high visible light transmittance (VLT) to ensure transparency while effectively blocking harmful UV and IR rays.

Top suppliers can customize VLT values by adjusting nano heat-insulating materials within the film. This balance between transparency and insulation helps you deliver glass products that look great, reduce glare, and save energy. When inspecting samples, check for haze, color uniformity, and optical distortion under various lighting conditions.

3. Safety and Impact Resistance

A major reason buyers choose PVB Interlayer Film is its safety performance. When glass breaks, the film holds fragments together, preventing injuries and maintaining structural integrity.

High-quality films exhibit strong penetration resistance, meaning they can withstand impacts from sharp or heavy objects. This makes them ideal for applications like bulletproof glass, safety windows, or curtain walls.

Before purchasing, confirm that the supplier’s PVB Interlayer Film has undergone certified impact testing and demonstrates stable performance in both high and low temperatures.

4. Soundproof and Energy-Saving Function

Beyond safety and clarity, many buyers overlook two additional performance areas — sound insulation and energy efficiency.

The molecular structure of PVB Interlayer Film provides a natural damping effect, which reduces sound transmission. This is especially valuable for buildings near airports, hotels, or hospitals that require quieter environments.

At the same time, laminated glass made with PVB Interlayer Film can block infrared rays, improving insulation and reducing air-conditioning costs. This combination of acoustic and thermal performance directly translates into higher value for your clients and better energy ratings for your projects.

5. Durability and Environmental Stability

Your investment in PVB Interlayer Film should last for years, not months. Therefore, durability is a critical quality metric. The film must resist moisture, UV radiation, and temperature fluctuations without losing its elasticity or adhesion.

A well-engineered PVB Interlayer Film maintains its flexibility in both hot and cold climates, ensuring consistent performance over time. Ask for long-term aging test results that demonstrate resistance to yellowing, shrinkage, and brittleness. These metrics help predict how your laminated glass will perform in real-world conditions.

Partnering with Xiaoshi Technology — Reliable Quality, Consistent Supply

At Xiaoshi Technology, we understand that buyers are not only looking for a product but a long-term partner they can trust. Our PVB Interlayer Film is engineered using advanced polymer processing and nano heat-insulation technology to deliver exceptional safety, clarity, and energy efficiency.

We operate under strict quality control systems that cover every stage — from raw material selection to extrusion and packaging. Each batch of PVB Interlayer Film is tested for adhesion, optical clarity, and environmental durability to ensure consistent results.

By choosing Xiaoshi Technology, you gain:

Stable and reliable supply for global orders

Custom thickness and performance options to fit diverse applications

Technical support and after-sales service for smooth project execution

In a market where reliability defines success, Xiaoshi Technology’s PVB Interlayer Film helps you stay ahead — with safer glass, higher efficiency, and lower total costs.

Post time: Oct-11-2025