-

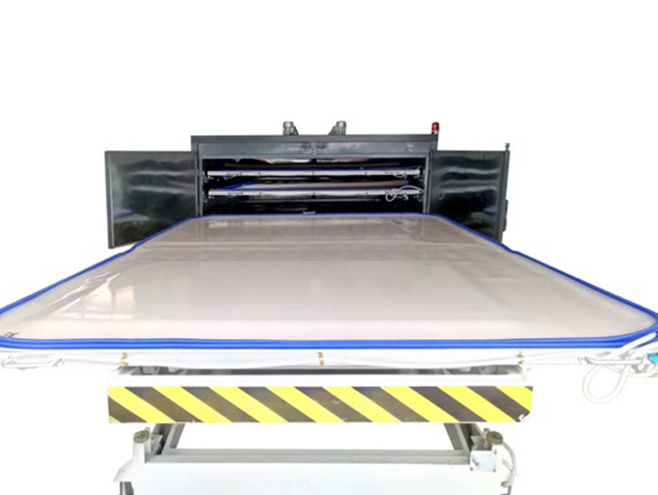

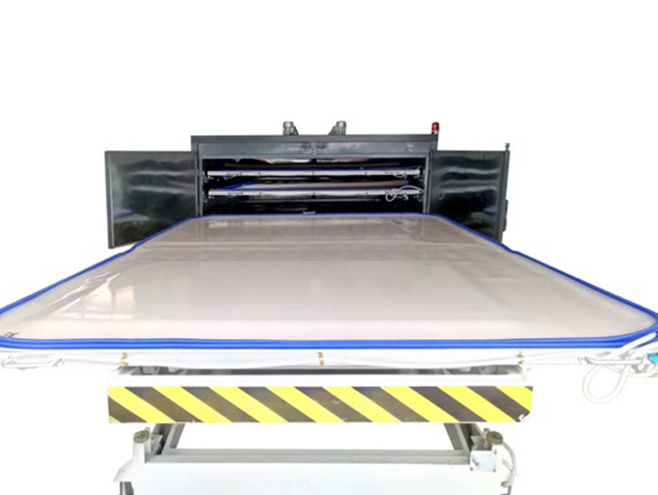

Glass Lamination Machine

The Glass Lamination Machine with heat and vacuum system is suitable for processing different types of safety glass lamination. Architecture glass lamiantion, tempered glass lamination, bending glass lamination, LOW-E glass lamination, PDLC smart switchable glass lamiantion and Decorative insert glass lamination.

-

PDLC film cutting machine

PDLC film cutting machine is compressed by air pressure, and the pneumatic push knife is used for cutting, which can realize single-person operation and save labor costs. The operating platform is affixed with a ruler, which is convenient for employees to operate.The cutting method adopts the upper and lower knife body cutting type cutting, and the incision is smooth and free of burrs.

-

Diamond Tools

These Diamond Tools are designed to cut through glass, tile with ease. Made of high carbon steel with industrial grade carbide tip for long life and efficient drilling. Diamond hole saw creates a high precision, smooth cut with no broken edges. Reduced drill speeds, low drill pressure and increased use of water lubrication will extend drill bit life considerably.

-

Glass processing tools

Tools for glass cutting, polishing and carrying. Synthetic diamond cystal ,diamond powder,diamond paste,electorplated diamond plate and wheel,diamond saw,PCD,diamond dermbabrasion,ceramic bond tools,metal band tools,resin bond tools,marble cutting blade and TCT saw blade.

-

Insulating glass production line

Vertical Automatic Insulating Glass Production Line is a high-efficiency insulating glass processing equipment. This line can not only produce ordinary insulating glass but also for low-e insulating glass. It is a better mass production equipment to produce insulating glass with high automatic degree, high efficiency, easiness of operation and maintenance

-

Two Component Manual Sealant Spreading Machine

Two-component sealant spreading machine is a device specially used for two-component sealant or Poly-sulfide sealant. It has two independent sealant containers. It can pass the sealant through the mixer at the same time or alternately. After mixing, it is transported to the machine head for gluing. The advantage of the two-component sealant spreading machine is that the Glue extrusion amount can be adjusted to adapt to different production needs, and the quality and efficiency can be guaranteed.

The two-component glue machine also has the advantages of easy use, easy operation, and uniform mixing.

-

Hot melt glue machine (Insulated glass equipment)

The hot melt glue Machine is an equipment specially used for hot melt adhesive coating. It has the characteristics of high efficiency, high precision and high reliability. Hot melt glue dispensing machine consists of heating device, glue gun, glue pump, glue dispensing device, control system, etc. The heating device is the core part of the entire equipment. It can heat the hot melt adhesive to a certain temperature to make it have better fluidity. The glue gun and glue pump transport the heated hot melt glue to the gluing device. The gluing device usually consists of a rotating shaft and multiple gluing heads. The rotating shaft drives the gluing heads to rotate to achieve hot melt glue dispensing. Spread evenly. The control system can accurately control the temperature, pressure, speed, etc. of the equipment to ensure the stability and accuracy of coating.

-

Rotary Coating Table

The insulating glass sealant Rotary Coating Table is a working table designed for insulating glass sealing. It consists a rotating table, a fixed frame, and a gluing machine. It has sufficient stability and load-bearing capacity. The rotating table can rotate 360 degrees to facilitate the operator to apply sealant to different parts of the insulating glass. The amount and speed of glue can be adjusted as needed. This avoids problems such as unevenness and omissions that easily occur when gluing by hand. At the same time, the equipment also has the advantages of simple structure, convenient operation, and easy maintenance, which can improve production efficiency and product quality, and reduce production costs and labor costs.

-

Intelligent Insulating Glass Inflator

The insulating glass inflator is a process equipment used to produce double-layer insulating glass. This equipment can improve working efficiency and production efficiency. The finished glass has high thermal insulation performance and can meet customer requirements for safe and energy-saving building doors and windows.

-

Automatic Argon Gas Filling Machine

Insulating Glass Inert Gas Filling Machine is specialized for filling inert gas (argon) into double-glazing glass. The machine is efficient that it can fill TWENTY pieces of insulating glass at the same time. The core controlling unit is Germany Siemens PLC.

-

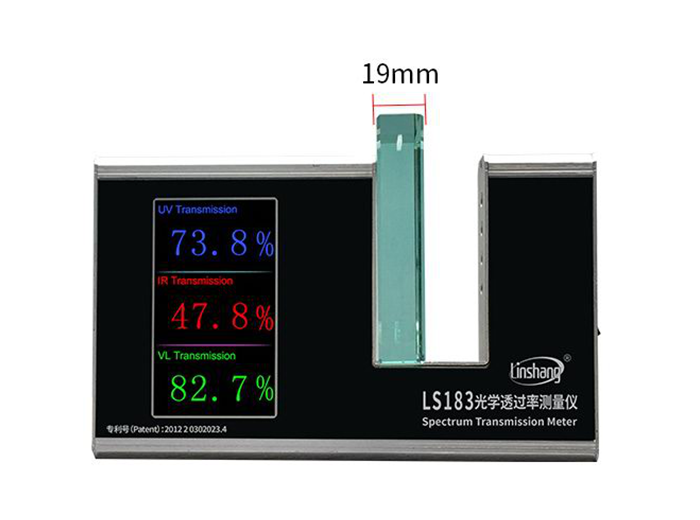

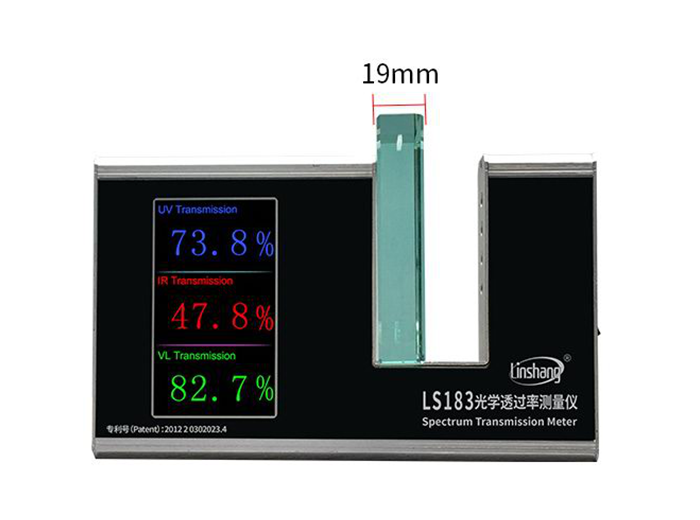

Light Transmittance Meter

UV transmittance meter, infrared transmittance meter, visible light transmittance meter (light transmittance meter). Three functions in one device. We just need to put the measured sample into the test slot and the three test results will be displayed on the interface immediately at the same time. The spectrum transmission meter has large LCD display, three different display interfaces can be switched.

-

Thermometer

Thermocouple is one of the most commonly used industrial elements in temperature measuring which is formed when 2 dissimilar metals are joined as a circuit with thermo current generated from the temperature difference between the metals.If there is any temperature difference between the thermocouple tip and reference end of the thermocouple, the instrument will display the temperature value versus the thermo emf generated from the thermocouple. On-site measurement and long distance transmission can both be carried out.