In the ever-evolving world of glass processing, having the right equipment can make a significant difference. At Xiaoshi(Sourceglas®), we pride ourselves on being a professional supplier and exporter of Glass processing machinery. Our commitment to innovation and excellence has led us to develop vertical glass washing machine that can be integrated with existing equipment, offering customization options tailored to your needs, including height, length, operating speed, and maximum glass thickness.

The following article provides an in-depth look at the features and benefits of vertical glass washing machines.

Why Choose Vertical Glass Machine?

1. Space-Saving and Adaptable

· Vertical Layout: The vertical design occupies a small floor area, making it ideal for space-constrained factories or workshops, and is particularly suitable for small- to medium-sized production or on-site operations.

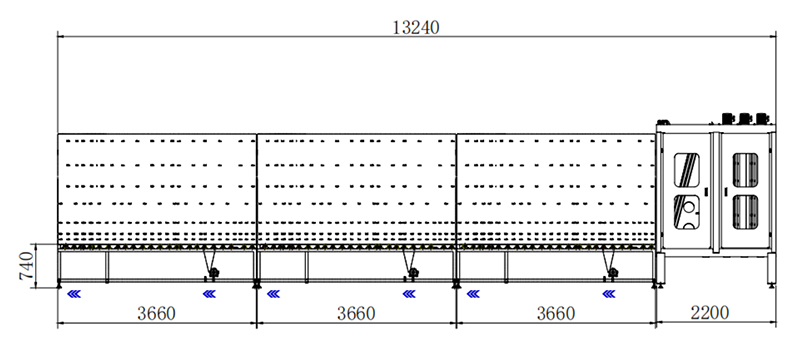

· Modular Design: Some models offer flexible adjustment of the cleaning height and width to accommodate different glass sizes (such as extra-long and extra-wide glass), improving equipment utilization.

2. Efficient Cleaning and Stable Quality

· Uniform Cleaning: The vertical conveyor system ensures stable cleaning of the glass during cleaning, eliminating uneven cleaning and glass slippage that can occur with horizontal conveyor systems.

· High Capacity: The continuous operation design enables rapid cleaning, suitable for large-scale production needs.

3. High degree of automation and easy operation

·PLC control system: Automated operation is achieved through a programmable logic controller (PLC), allowing preset cleaning parameters (such as water temperature, pressure, and speed) to reduce manual intervention.

·Safety protection: Integrated safety devices such as an emergency stop button and photoelectric sensors ensure operator safety.

4. Energy-saving, reducing operating costs

· Water circulation system: Select models are equipped with a circulating filter device that recycles and filters wash water, reducing water consumption and wastewater discharge.

· Energy-saving design: High-efficiency motors and variable frequency drive technology reduce energy consumption; the hot air drying system optimizes heat utilization and reduces energy waste.

· Low maintenance costs: The modular structure facilitates component replacement and repair, extending the service life of the equipment.

5. Wide Range of Applications and Diverse Functions

· Compatible with multiple materials: Cleans standard glass, low-emissivity (Low-E) glass, laminated glass, coated glass, and more, meeting the needs of various industries.

· Customization Options: Customizes options such as edge grinding, and CNC cutting to achieve integrated processing.

6. Reduced Labor Intensity and Improved Safety

· Automated Operation: Reduces manual handling and cleaning operations, reducing worker workload and preventing the risk of scratches and falls associated with manual cleaning.

· Enclosed Design: The cleaning process is completed within a sealed chamber, minimizing the risk of chemical cleaning agents to operators.

Vertical glass washing machine, with its vertical design, automated control, efficient cleaning, and energy-saving and environmentally friendly features, have become a core piece of equipment in the modern glass processing industry. It not only improve production efficiency and product quality, but also reduce operating costs and safety risks. It is particularly suitable for applications requiring high cleanliness and large production volumes.

If you are interested in purchasing or replacing your existing glass washing equipment, please contact me at info@sourceglas.com.

Post time: Oct-28-2025