Are Your Glass Lamination Machines Delivering the Quality and Efficiency Your Business Needs? If you're in the glass processing industry, you know that not all Glass Lamination Machines are created equal. The wrong equipment can mean wasted materials, inconsistent quality, and lost production time. Professional-grade machines make all the difference in your bottom line.

Here are the 7 key features that set high-performance Glass Lamination Machines apart from basic models:

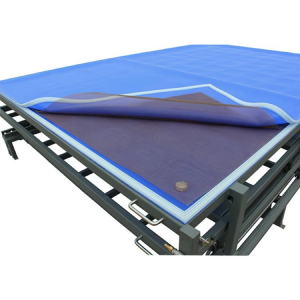

1. Vacuum Lamination Technology Without Autoclave

Modern Glass Lamination Furnaces eliminate the need for autoclave processing. Using advanced vacuum systems with silicone bags, they achieve perfect lamination through controlled heating under vacuum conditions.

This innovative approach offers simpler operation, 30-40% lower energy consumption, and significantly reduced initial investment compared to traditional autoclave systems. The vacuum technology ensures uniform pressure distribution for flawless results across all glass types - from architectural panels to curved tempered glass.

2. Multi-Layer Processing Capacity

Professional-grade machines feature isolated multi-layer chambers that dramatically improve production efficiency. This intelligent design allows simultaneous processing of multiple glass panels, saving electricity, reducing labor costs, and shortening production cycles.

The prefabricated duplex configuration boosts output by enabling single-station equipment to handle double the capacity, effectively lowering your per-unit production costs.

3. Precision Temperature Control System

The horizontal thermal circulation system ensures even heat distribution across all surfaces of the vacuum bag. Combined with high-grade thermal insulation materials that form double protection, the furnace achieves fast and uniform heating.

The intelligent thermostat allows programmable automation of the entire process, with temperature precisely monitored and adjusted through user-friendly touchscreen controls. This level of control is crucial when working with sensitive materials like LOW-E or PDLC smart glass.

4. Versatile Material Compatibility

Top-tier Glass Lamination Machines handle diverse materials with equal excellence. Whether you're processing EVA film for standard laminated glass, producing decorative insert glass, or creating specialized products like switchable PDLC glass, these machines maintain consistent quality. The system accommodates various glass types including tempered, bent, and architectural glass with minimal adjustment time between production runs.

5. Energy-Efficient Operation

The combination of vacuum technology and advanced insulation results in remarkable energy savings. The isolated chambers prevent heat loss, while the efficient thermal circulation system minimizes energy waste. These features typically reduce operational costs by 35-45% compared to conventional autoclave systems, with the added benefit of a smaller carbon footprint for environmentally conscious manufacturers.

6. Intelligent Safety Features

Professional machines incorporate multiple safety systems including leakage protection devices and automatic alarms. The durable silicone vacuum bags maintain excellent airtightness throughout the lamination process, while quality vacuum pumps ensure consistent performance. These features work together to minimize defects and ensure operator safety, particularly important when processing high-value specialty glass products.

7. Simplified Operation with Smart Controls

The latest Glass Lamination Furnaces feature one-touch operation with programmable automation. The intuitive touchscreen interface allows operators to monitor and control the entire process with minimal training. Automatic alarms notify staff of any process deviations, while the system's ability to store customized programs for different glass types significantly reduces setup time between production runs.

Why Choose Xiaoshi Technology for Your Glass Lamination Needs?

Our vacuum laminating furnaces are designed for professionals who demand:

- Superior Quality: Uniform lamination for all glass types, including tempered, curved, and smart glass

- Increased Productivity: Multi-layer processing and duplex configurations boost output by up to 100%

- Energy Savings: 35-45% lower operating costs than traditional autoclave systems

- Easy Operation: Intuitive touchscreen controls with programmable automation

- Comprehensive Support: 24/7 technical assistance and operator training

Our product range includes:

- Standard models for entry-level production

- High-capacity systems for large-scale operations

Custom solutions for specialized applications like PDLC smart glass

Xiaoshi Technology specializes in advanced Glass Lamination Machines that combine German engineering precision with Chinese manufacturing efficiency. Choose Xiaoshi Technology for reliable performance, lower costs, and a partner committed to your success.

Post time: Jul-08-2025