Low-E glass lamination technology is an advanced glass processing technology that mainly optimizes the energy saving, heat insulation, lighting and other aspects of glass through special treatment on the glass surface. Here’s an in-depth look at Low-E glass lamination technology:

1. Basic concepts

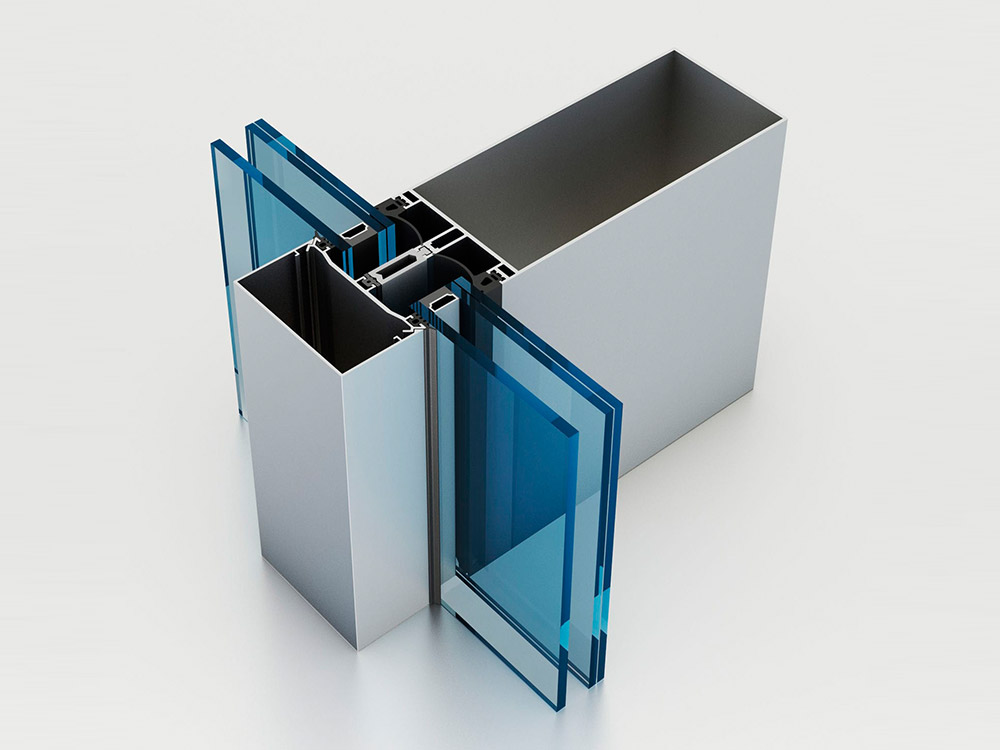

Low-E glass, the full name of low-emissivity coated glass, is coated with one or more special metal films on its surface. These films can effectively control the transmission of visible light, ultraviolet and infrared rays, thereby improving the thermal insulation performance and energy saving of the glass. Effect. Low-E glass lamination technology combines Low-E glass with other glasses or materials through a lamination process to form a composite structure to enhance its overall performance and safety.

2. Application scenarios

Low-E glass lamination technology is widely used in construction, automobiles, solar energy and other fields. In the field of construction, it is often used in exterior curtain walls, doors, windows, sun rooms and other parts of high-rise buildings, as well as display windows and other parts of commercial buildings to provide good heat insulation, lighting and safety performance for the building.

3. Key steps

The key steps of Low-E glass lamination technology mainly include pre-treatment, coating, lamination and curing. The pre-treatment stage is mainly to clean and dry the glass surface to ensure the quality of the coating. The coating stage uses a specific process to form a Low-E film layer on the glass surface. The lamination stage is to glue Low-E glass and other glasses or materials together through lamination to form a composite structure. The curing stage is to solidify the laminate glue through heating or pressure to enhance the strength and stability of the composite structure.

4. Key points of process

The process points of Low-E glass lamination technology include the following points:

I, Choose suitable interlayer film: Ensure the interlayer film (EVA, PVB or Ionoplast S.G.P) is evenly applied on the glass surface to avoid problems such as uneven film thickness or peeling off.

II, Energy-saving performance: By adjusting the material and structure of the laminated glass interlayer film , the thermal insulation performance and light transmission performance of Low-E glass are optimized to maximize the energy-saving effect.

III, Safety: During the Low E glass lamination process, high-strength interlayer film and appropriate curing processes are used to ensure the impact resistance and wind pressure resistance of the composite structure and improve the safety of the building.

In summary, Low-E glass lamination technology is a glass processing technology with broad application prospects. Through in-depth study of its basic concepts, application scenarios, key steps and process points, this technology can be better understood and applied, providing strong support for the development of construction and other fields. Welcome to contact us if you need more support! info@sourceglas.com

Post time: Apr-07-2024