Laminated glass is made of two or more pieces of glass with one or more layers of interlayer films between them. A bonded composite glass product. There are variety types of interlayers, like PVB, EVA, ionoplast interlayer film (Known as SGP),etc.

Laminated glass is gaining more and more attention due to its high safety. In the field of architectural glass, it is hard to say which type of interlayer film is more popular, because they have different product characteristics, each has its own advantages.

EVA interlayer film

The full name of EVA is ethylene-vinyl acetate copolymer, which has water resistance and corrosion resistance. Compared with PVB film or ionoplast interlayer film, it has a lower melting temperature and good fluidity, it can be operate at 110℃-120℃and the finished glass transparency and adhesion strength are both qualified.

A Simple oven with vacuum and heat will meet the production needs of EVA lamination, so the investment in production equipment is small, and occupies a small area for equipment installation.

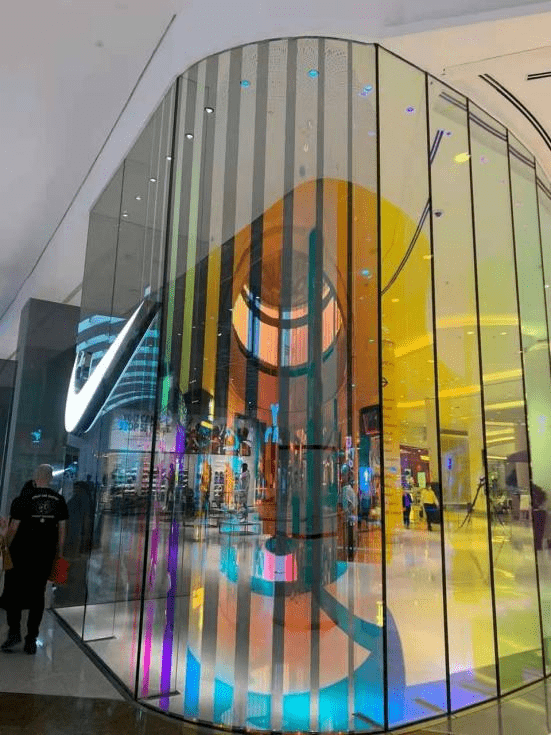

Due to the good fluidity of the EVA film, it is suitable for variety types of insert layer lamination which make decorative glass with rich patterns.

PVB interlayer film

The full name of PVB is polyvinyl butyral, which has high transparency, cold resistance, impact resistance and ultraviolet radiation resistance.

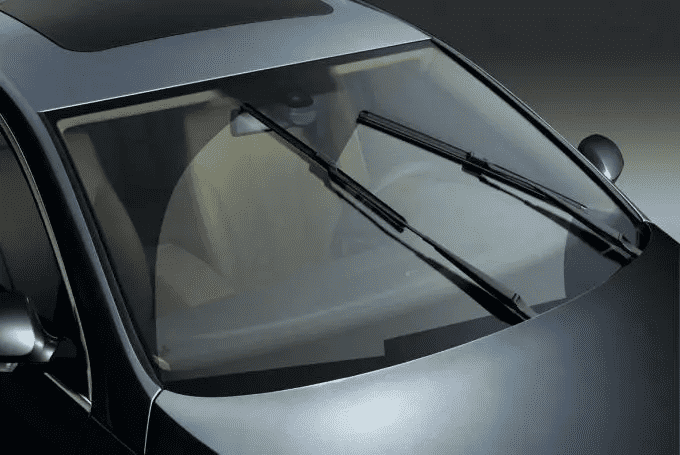

PVB film is currently the most widely used interlayer material for architectural glass and automotive glass lamination. Compared with EVA interlayer film, the storage and operation conditions are much more complicated. Generally, it request a room with stable temperature(between 18-23℃) and humidity (18-23%) to do the film and glass sandwich. And the moisture content of PVB film should between 0.4%-0.6%. After preheating and rolling or vacuuming, heating up the temperature of autoclave, keep the heat(at 120-130℃)and pressure(1.0-1.3MPa ) for 30-60 minutes.

PVB laminated glass has good safety, sound insulation and UV resistance, but PVB has poor water resistance, and it is easy to fall off after long-term wet immersion.

Ionoplast interlayer film

Most people are know the name of SGP (Sentry Glas Plus), which is a high-performance interlayer material developed by DuPont. But now more and more Chinese manufacturer are producing their own brand of ionoplast film. Because the ionoplast interlayer film has good edge stability and not sensitive to moisture.

The production process of ionoplast film is similar to that of PVB film, and the equipment is autoclave also.

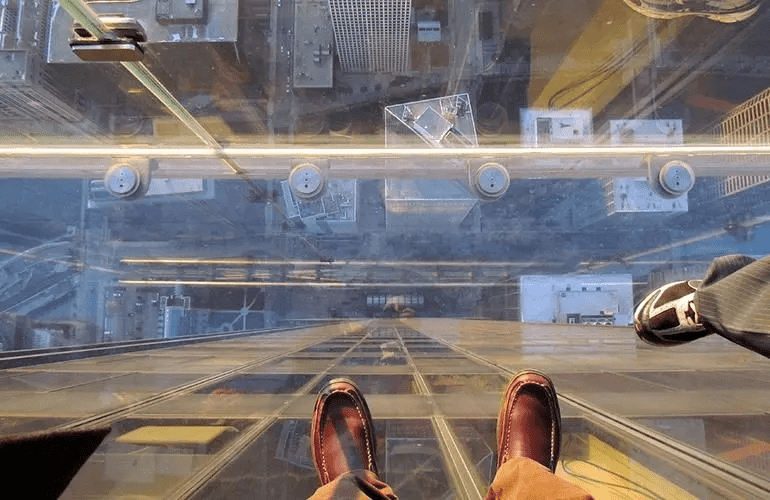

Ionoplast interlayer film laminated glass not only has high strength, but also has sufficient bending resistance after being damaged, so that the whole piece will not fall from a high altitude, so it is especially suitable for horizontal or oblique glass panels of glass lighting roofs.

Ionoplast interlayer film has not been used in building curtain wall laminated glass for a long time, but its excellent performance has already appeared in the application. The high load-bearing capacity, safety and permeability of Ionoplast interlayer film laminated glass are fully demonstrated in the glass curtain walls of large public buildings and super high-rise buildings. In the application of glass balustrade, glass floor, and glass sunshade, Ionoplast interlayer film has the advantages of impact resistance, safety, and no need for edge sealing. In the near future, we will see its broader development prospects.

Post time: Jun-08-2023