Factory For Thermo cutter - Glass Lamination Machine – Xiaoshi

Factory For Thermo cutter - Glass Lamination Machine – Xiaoshi Detail:

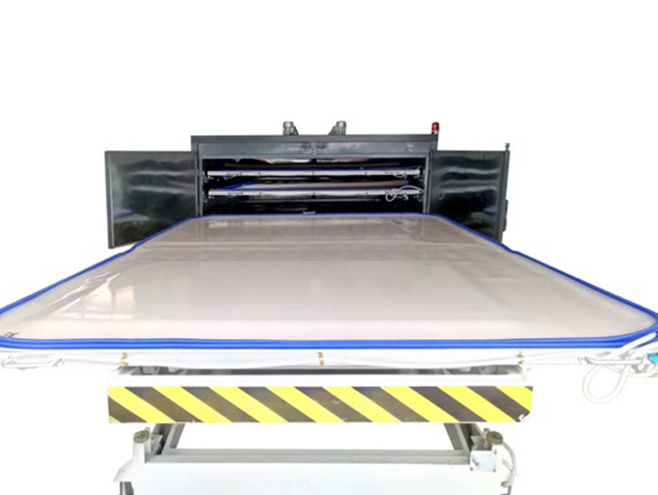

Glass lamination furnace

The Glass Lamination Machine with heat and vacuum system is suitable for processing different types of safety glass lamination. Architecture glass lamination, tempered glass lamination, bending glass lamination, LOW-E glass lamination, PDLC smart switchable glass lamination and Decorative insert glass lamination.

Unlike autoclave, it does not need rolling, and can be completed by heating under vacuum conditions. Compared with the autoclave, the vacuum laminating furnace is simple in operation, low consumption in energy, Low investment and high in efficiency.

The construction of glass lamination furnace include furnace body, electrical control system, vacuum system, thermal circulation system, cooling system, loading and unloading system. The furnace body adopts a steel structure, and two high-grade thermal insulation materials are used in the furnace to form a double protection. The control system is an intelligent thermostat, which can be programmed to complete the entire process automatically and manually. Using high-quality vacuum pump, the silicone vacuum bag is durable and has good air tightness. The heating device adopts a horizontal thermal circulation system, so that the upper and lower surfaces of each vacuum bag are heated evenly which will have improve the finished glass quality.

It can be used to produce laminated glass for guardrail, curtain wall, canopy, curved steel lamination, tempered lamination and other construction engineering glass

Product description and advantages

The glass furnace was designed for EVA film which can laminate two or more pieces of glass together, using vacuum system (silicone bag) with high temperature heating to process the EVA film.

Features:

By constantly temperature ventilation for heating, the furnace temperature heating up fast and uniform.

The isolated chamber for multi layers can help save electricity, save energy, save time and labor.

Temperature read and controlled by touch screen. One button to start, automatically complete the alarm, automatic machine.

Prefabricated duplex configuration, the output increases, the equipment from single-station upgrade to double-bit, reduce costs and increase production.

Leakage protection device to ensure safety operation and reduce the percentage of defects.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Factory For Thermo cutter - Glass Lamination Machine – Xiaoshi , The product will supply to all over the world, such as: Frankfurt, Greenland, Seychelles, During the 10 years of operating, our company always try our best to bring consumption satisfaction for user, built a brand name for ourselves and a solid position in the international market with major partners come from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. Last but not least, price of our products are very suitable and have fairly high competition with other companies.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.