Intelligent glass loading and cutting machine

The Intelligent glass loading and cutting machine has functions automatic loading, automatic pressure control, automatic edge finding, optimization software, air flotation system, with breaking table. 360 degree remote control walking, with the advantages of small footprint, easy mobility and high efficiency.

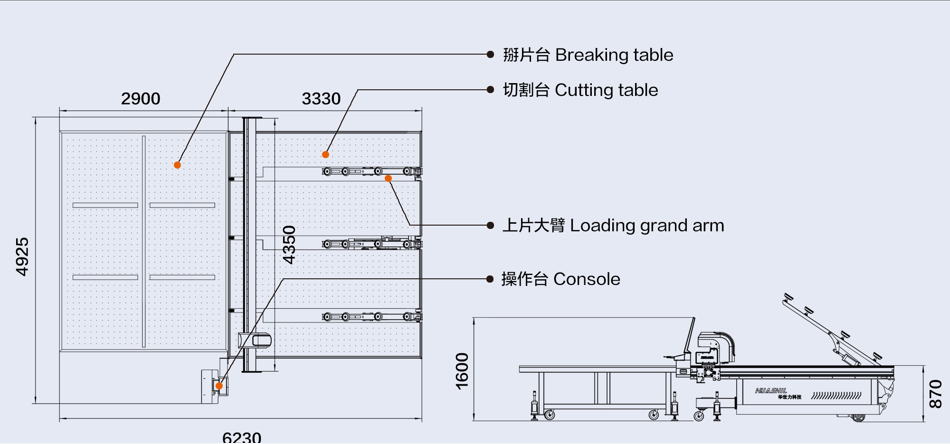

The intelligent glass loading and cutting machine consists of two systems: loading and cutting machine and air-floating breaking table. It integrates automatic loading, automatic optimization layout, automatic labeling, automatic cutting, automatic transportation and air-floating breaking table, and realizes automatic operation of glass cutting process. The machine is equipped with power walking wheels, which can be controlled by remote control in the working area for easy shifting. The machine can realize straight and special-shaped cutting of glass, and is suitable for architectural glass, furniture glass, craft glass, decorative glass, cabinet glass, glass mirror, etc.

Performance characteristics

1, Cutting technology and automatic oil supply

2, Optimization software and special-shaped libraries

3, Automatic edge positioning and intelligent special-shaped scanning

4, Telescopic boom and automatic loading

5, Machine walking and cylinder locking

6, Air floating countertop

7, Breaking table and auxiliary breaking ejector rod

8, Glass conveying

9, Automatic rail lubrication

10, Servo motor direct drive structure

11, Automatic voltage control and voltage detection

12, Voltage detection

13, Automatic Labeling (Optional)

14, High performance Low E removal device(Optional)

Technical Parameters

| Cutting Range | 3660mm*2800mm | 3660mm*2400mm |

| Floor Area | 5780*4925*1600mm | 5550*4925*1600mm |

| Cutting Table size | 3330mm*3900mm | 3100*4925*1600mm |

| Splitting Table surface |

2450**3800*880mm |

|

| Cutting Thickness |

3-19mm |

|

| Cutting Speed |

0-200mm/min |

|

| Table Height |

870mm( Adjustable) |

|

| Console Height |

1000mm |

|