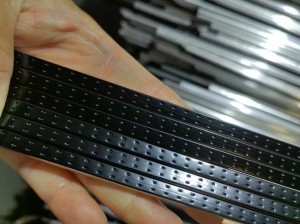

Aluminum Spacer bar

Product Description

Insulating glass Aluminum Spacer bar, also named as warm edge, it has characters with sound insulation, heat insulation, energy saving, safety, anti - fog and other functions applicable to building curtain wall, Windows and doors glass, trains, ships, aircraft, refrigerators.

Since the 1960s, the gradual emergence and widespread use of modern insulating glass materials, including aluminum metal spacers, organic sealants (from single-channel seals to today's double-channel seals dominate) and 3A molecular sieves, have made The sealing performance of the insulating glass is improved, forming the current insulating glass structure.

Traditional insulating glass uses aluminum metal spacers. The thermal conductivity of aluminum metal spacers is large. In order to solve the problem of heat loss at the edge of insulating glass, warm-edge spacers emerge as the times require, and warm-edge spacers are widely used in developed countries. According to statistics, in 1990, the cold-edge insulating glass accounted for 85% of the market share, and the warm-edge was only 15%, but in 2000, the warm-edge reached 80%, and the cold-edge dropped to 20%. So what exactly does the warm edge strip mean? The warm edge spacer strip is a kind of partition material used between double-layer glass. It is processed by the process of hot and cold co-extrusion, in order to achieve thermal insulation and noise reduction. A material used for functions. The cavity is composed of aluminum or aluminum alloy material, which is used to fill the desiccant, isolate the original insulating glass sheet, and play a supporting role as a structural product. The low thermal conductivity of the warm edge spacer can achieve excellent thermal insulation performance and increase the temperature of the inner edge of the insulating glass. The thermal conductivity of the traditional aluminum spacer is about 1500 times that of the composite warm edge spacer, and the energy saving effect is up to 100 times. If it is more than 5%, it can effectively reduce the U value of the whole window by 0.2-0.4w/m2k and reduce carbon emissions.

Use warm edge spacers to make the edge temperature difference of insulating glass more than 7°C. Warm edge spacers can significantly improve the energy-saving and thermal insulation effect of door, window and curtain wall systems, prevent condensation and frost on the edges of doors and windows, prevent the growth of mold and bacteria, and ensure a healthy indoor environment; various The color creates the decorative effect of doors and windows. At the same time, the warm edge spacer solves the long-standing contradiction between energy saving and durability of insulating glass, causing a revolution in the insulating glass industry, greatly improving the energy saving effect and service life of door and window glass. At present, spacers have been widely used in developed countries such as Europe and the United States, with a penetration rate of more than 90%. With the improvement of building energy conservation requirements in my country, warm edge spacers will be widely used.

Product Advantages:

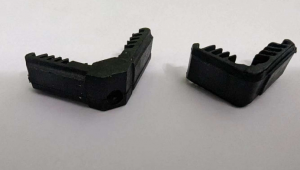

1. Unique design profiles, excellent bending property.

2. Unique surface treatment, better sealing properties with sealants.

3. High-frequency induction welded, continuous welding seam quality monitoring by eddy current system.

4. No burr and no deformation after cutting, better for connected.

Technical Data:

| Item | Unit | Bead | Pellet | Test condition | ||

| Diameter | mm | 1.6--2.5 | 3--5 | 1/16" | 1/8" | |

| Static water adsorption | ≥%wt | 21.5 | 21.5 | 21.5 | 21.5 | RH10%,25°C |

| Bulk density | ≥g/ml | 0.7 | 0.7 | 0.65 | 0.65 | Settled |

| Loss on ignition | ≤%wt | 1.5 | 1.5 | 1.5 | 1.5 | 575°C,1H |

| Loss on attrition | ≤%wt | 0.1 | 0.1 | 0.2 | 0.2 | |

| Crush strength | ≥N | 30 | 80 | 40 | 70 | |

| Partical ratio | ≥% | 97 | 99 | |||

| Water content | ≤% | 1.5 | 1.5 | 1.5 | 1.5 | |