Liquid Peelable Film

Application:

glass curtain wall, aluminum doors and windows, stainless steel parts, automobile transportation protection, elevator engineering, glass fiber reinforced plastic products, metal rust prevention, large construction machinery, spray booth barrier protection, etc.

Product properties:

Appearance: blue or colorless colloidal liquid

Solid content: ≥40%

PH value: 7.0~8.0

Viscosity: 1000~3000(mPa.s)

Performance characteristics:

1. Water-based system, free of heavy metals, halogen-free, in line with SGS and RoHs standards.

2. The protection period in the natural environment can reach more than one year, and it can still be peeled off.

3. It can be used on a variety of substrate surfaces, the film body can be peeled off as a whole without residue, and has anti-fouling and anti-rust properties.

4. Protection of metal, glass, stone, wood, ceramics and other substrates.

5. To achieve easy peeling, 10-15 square meters can be sprayed per kilogram.

6. Flexible construction process, suitable for spraying, roller coating, brushing and other processes.

7. The construction is convenient, special-shaped materials are still applicable, and labor costs are saved.

8. Overcome the aging resistance of traditional film.

Construction technology:

1. Substrate surface cleaning

Before construction, oil stains and water stains on the surface of the substrate should be removed, dried with cotton yarn or towel, and the surface of the substrate should be kept dry. If there is floating ash or dust on the surface, it can be directly applied without affecting the normal use of the product.

2. Construction environment

During the construction of the peelable protective film, the ambient temperature shall not be lower than 5 ℃. When the wind speed is greater than 5m/s, it is not suitable for construction.

3. Construction tools

Air compressor, pneumatic spray gun, roller or wool brush.

4. Construction

4.1 This product can be applied by pneumatic spraying, roller coating or brushing with wool, and dry naturally. The specific method is similar to ordinary paint and paint construction.

4.2 It can be used after opening. Different processes can be diluted with water according to the process requirements. It is recommended to add 10-15% water for dilution when using the spraying process for horizontal substrates. It is recommended to add 8-12% water for vertical substrates using the spraying process. % water for dilution, it should be fully stirred before use. It can be used directly by roller coating or brush coating process. It is not recommended to add water.

4.3 According to the specific requirements of substrate protection, construction of different thicknesses can be carried out.

4.4 Taking 10 square meters per kilogram as an example, the film can be formed in about 60 minutes at 25°C, and the resistance and peeling effect can be achieved after 6 hours of film formation.

5. Peel off

Ready to use after opening. This product is sprayed with an electric sprayer or brushed with wool. If spraying is used, it is recommended to add about 5% to 10% of water to the tearable film latex to dilute it, stir evenly, and then spray. The spraying method is similar to that of latex paint. Dry and when not needed, just tear off with your fingers.

The drying time for film formation is as follows:

Temperature 20℃~30℃ for about 3~5 hours

Temperature 30℃~40℃ About 1~1.5 hours

Temperature 50℃~60℃ for about 15 minutes

When the peelable protective film is peeled off, the ambient temperature should be 5-35 ℃. If the temperature is too low, the protective film will become brittle, and if the temperature is too high, the protective film will become soft, which is not conducive to the peeling of the protective film.

Precautions:

Please confirm with a small sample before using in large quantities.

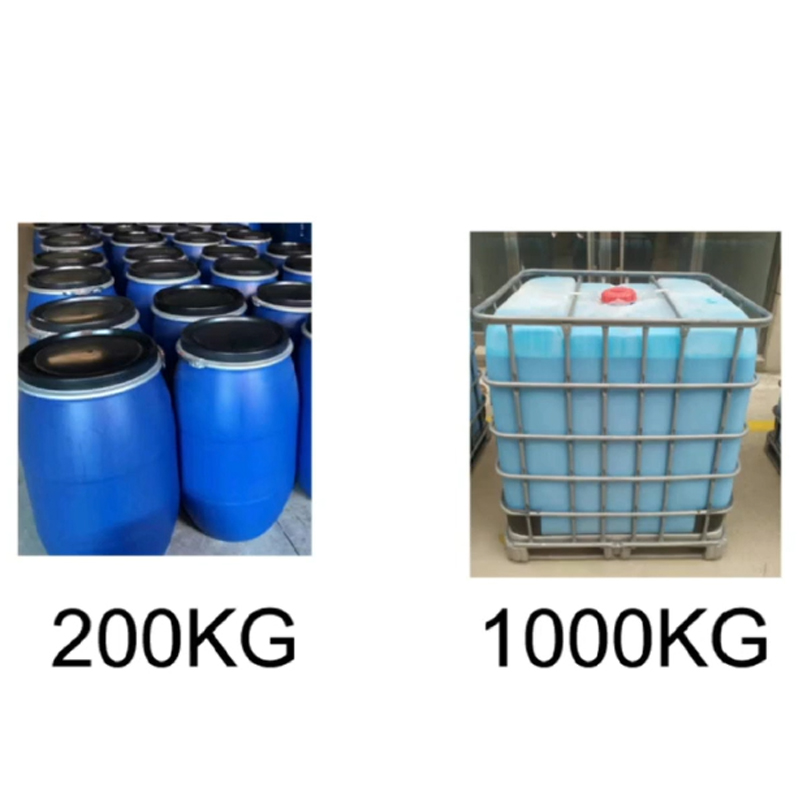

Packaging and Storage:

25Kg plastic drum airtight packaging. This product can be stored for a long time for one year.

This product should be stored at 5-35℃, in a dry and cool environment, avoid direct sunlight, keep away from heat and fire sources, and avoid frost.